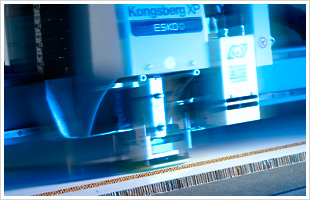

DMR Graphics installs Esko Kongsberg XP 24 cutting table

The Kongsberg XP introduces a completely new standard for digital cutting tables. It is designed so solidly that it provides accurate handling of even the most challenging materials.

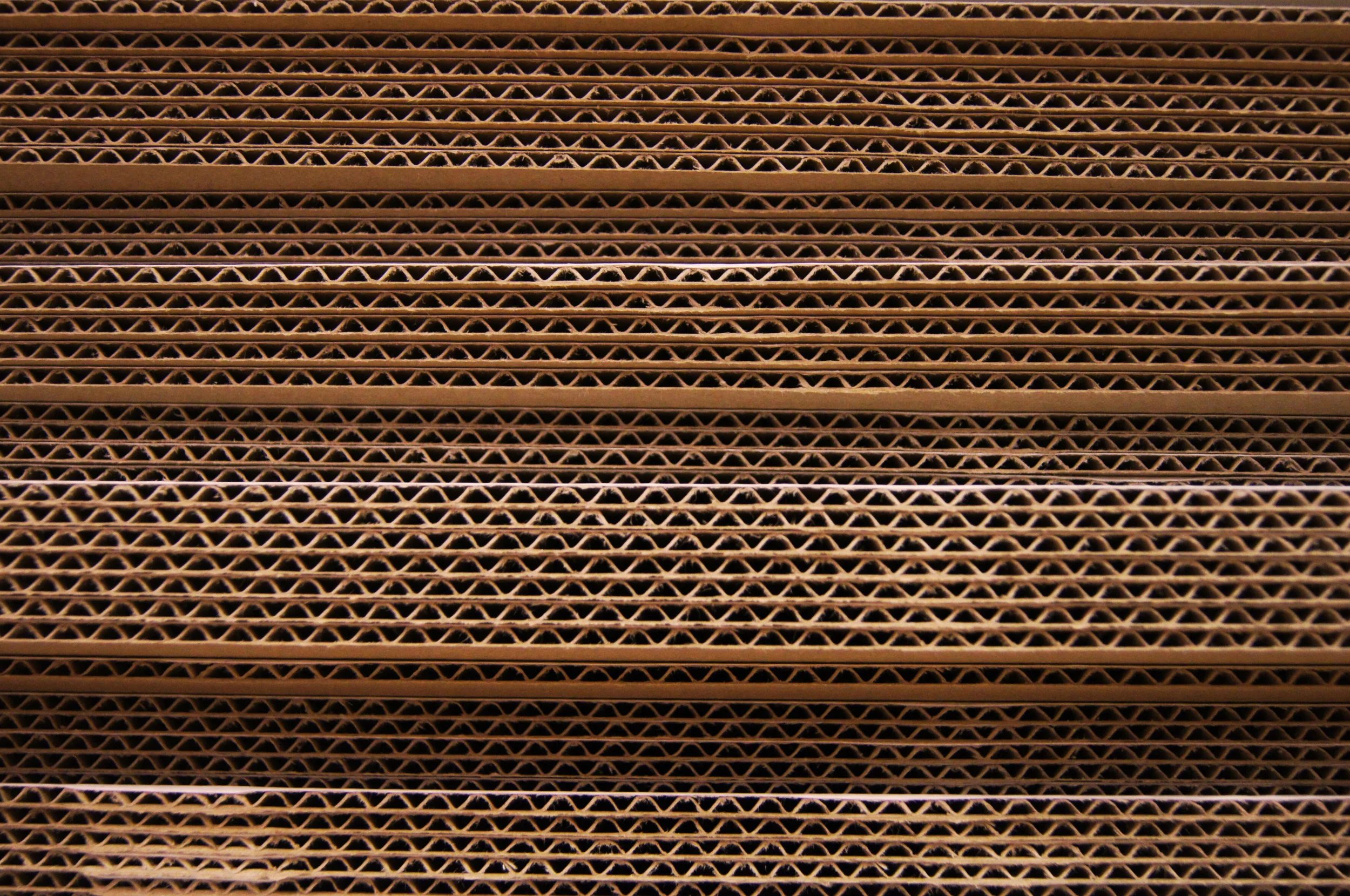

The Kongsberg XP offers a radically new level of productivity and throughput. It was made especially for handling the combination of corrugated board and other rigid or roll materials used in POP products and product displays.

An extensive array of available tools matches the wide range of materials that can be used.

What do you want to produce today?

Are you going to produce corrugated boxes today? Or a number of signs or POP displays? Perhaps you are facing a complex job with different materials?

With the Kongsberg XP CAD table, DMR Graphics is ready to run jobs from a single unit to a full scale production with up to a 1000 units in a day. The XP's production power and quick change of tools ensures on time delivery, every time, even for the complex jobs.

Benefits of CAM cutting

The benefits of CAM / CAD cutting with the Kongsberg XP are obvious:

- Process a wide array of materials

- Very short set-up time

- Extraordinary throughput and speed

- No need to wait for a die

- Integration with the CAD editor

- A range of very versatile tools

Unsurpassed throughput

The throughput delivered by Kongsberg XP CAD cutter represents a new standard for digital finishing. In fact, no other CAD cutting table on the market can even compete. For corrugated short runs digital finishing now challenges the throughput on manual clam shell die cutters.

By the way, throughput is more than the actual cutting speed. It also includes job preparation, vertical speed, idle time, and the speed of tool changes.

Several materials can be cut at top speed, 100 m/minute, and a displacement speed of 100 m/minute makes the XP more efficient even with materials that demand a reduced cutting speed.

Tool changing and automatic tool leveling

Changing tools is easy and very fast: changing a milling bit for instance is done in less than 20 seconds (including bit calibration). The system recognizes the tool units automatically, through electronic identifiers. The Kongsberg XP has an Automatic Tool Leveling feature that calibrates the vertical operating level of all the Kongsberg tools.

Changing a tool or milling bit will cause an automatic tool measurement to ensure cutting depth remains correct. Changing knifes, drills and milling bits no longer slows down production. It also becomes a lot safer because human errors are a thing of the past.

Let us know how DMR Graphics can help you today!